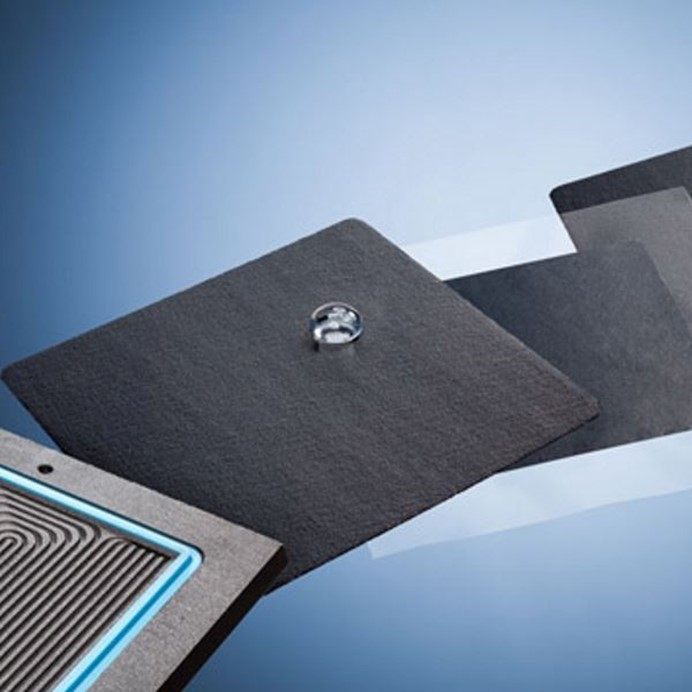

氣體擴(kuò)散層

科德寶是全球領(lǐng)先的非織造布供應(yīng)商。基于其高科技產(chǎn)品組合,科德寶為所有聚合物電解質(zhì)膜燃料電池 (PEMFC) 和直接甲醇燃料電池 (DMFC) 應(yīng)用提供 GDL 材料。

GDL 材料是燃料電池中的性能關(guān)鍵部件之一,既可作為膜電極組件 (MEA) 的功能結(jié)構(gòu),也可作為支撐結(jié)構(gòu)。

GDL 材料的卓越特性:科德寶 GDL 材料具有高導(dǎo)電性和導(dǎo)熱性,保護(hù)膜免受潛在的穿刺損壞,允許在 MEA 制造中進(jìn)行安全且高效的下游加工,并根據(jù)燃料電池運行條件為優(yōu)化質(zhì)量傳輸而量身定制。這種優(yōu)化確保向催化劑層提供足夠的氫氣和氧氣(空氣)氣體反應(yīng)物。同時,必須控制氣態(tài)和液態(tài)產(chǎn)物水的運動,以保持催化劑位點對反應(yīng)物開放,同時防止膜變干。

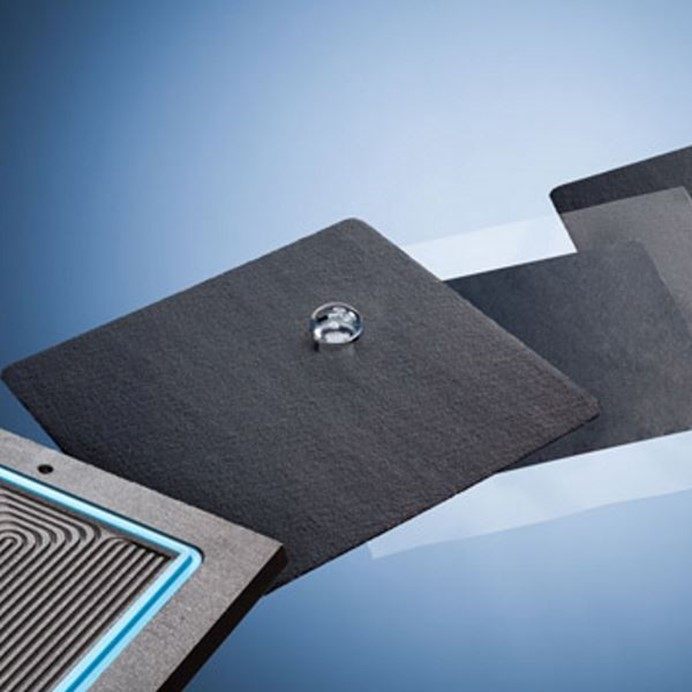

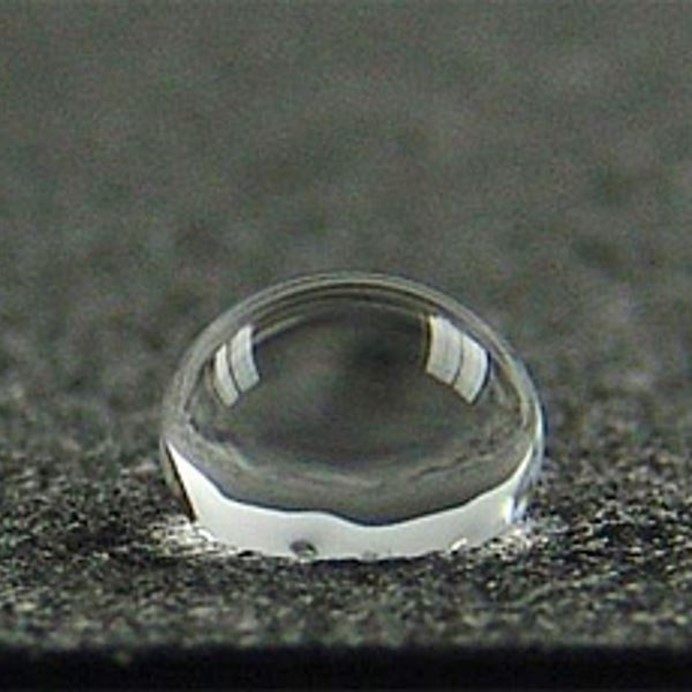

這種最重要的水管理主要是通過我們特殊配方的微孔層 (MPL) 涂層和處理來實現(xiàn)的,這些涂層和處理具有導(dǎo)電性和導(dǎo)熱性以及疏水性的完美平衡。最新一代的科德寶 GDL 涵蓋了廣泛的應(yīng)用;用于汽車,需要改進(jìn)的冷啟動行為和非常高的質(zhì)量傳輸能力,以實現(xiàn)高電流密度運行,用于高濕度的固定系統(tǒng),以及在開式陰極備用電源燃料電池中預(yù)期的極度干燥的運行條件。

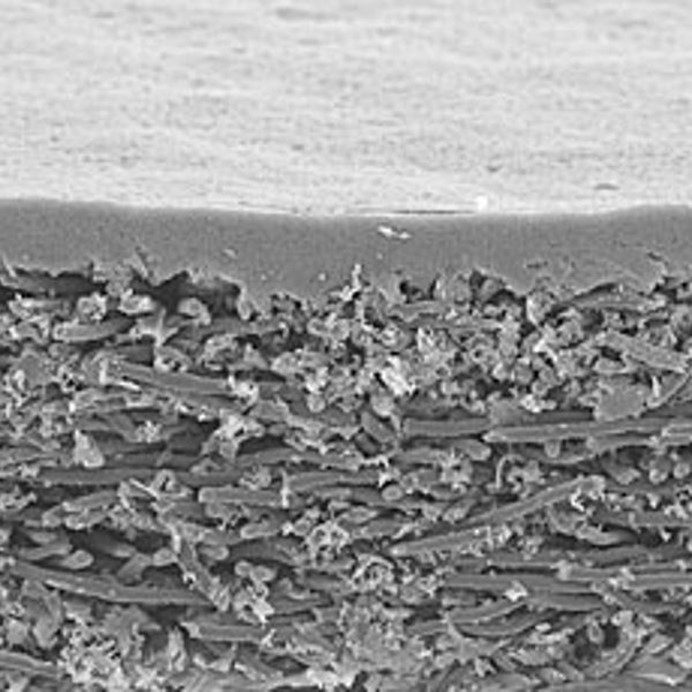

應(yīng)用科德寶發(fā)明的無紡布技術(shù),我們的 GDL 獨特的三維纖維結(jié)構(gòu)滿足了這些具有挑戰(zhàn)性的質(zhì)量傳輸要求,此外還提供了機(jī)械可壓縮性,有助于適應(yīng)雙極板和膜等電池堆組件的厚度變化。

請參閱我們的應(yīng)用顧問文件,為您的燃料電池應(yīng)用選擇合適的材料。除了燃料電池,科德寶的碳纖維基非織造布也非常適用于其他應(yīng)用,例如水解或儲能。

Gas Diffusion Layers

Freudenberg is worldwide the leading nonwoven supplier. Based on its high technology portfolio Freudenberg supplies GDL materials for all polymer electrolyte membrane fuel cell (PEMFC) and direct methanol fuel cell (DMFC) applications.

GDL materials are one of the performance critical components in fuel cells acting both as the functional as well as the supporting structure for membrane electrode assembly (MEA).

Superior characteristics of GDL materials: Freudenberg GDL materials exhibit high electrical and thermal conductance, protect the membrane from potential puncture damage, allow safe and productive downstream processing in MEA manufacturing, and are tailored for optimized mass transport according to the fuel cell operating conditions. This optimization ensures sufficient supply of the hydrogen and oxygen (air) gas reactants to the catalyst layers. Concurrently the movement of product water in gas and liquid states must be managed to keep catalyst sites open for reactants while preventing membrane dry-out.

This all-important water management is primarily achieved through our specially formulated micro-porous layer (MPL) coatings and treatments that have the perfect balance of electrical and thermal conductivity and hydrophobicity. The latest generation of Freudenberg GDL covers a wide range of applications; for automotive, which requires improved cold start behavior and very high mass transport capability for high current density operation, for highly humidified stationary systems, and for extremely dry operation conditions expected in open cathode back-up power fuel cells.

Applying the nonwoven technology invented by Freudenberg, our GDL's unique three dimensional fiber structures meet these challenging mass transport requirements and furthermore offer mechanical compressibility that helps to accommodate thickness variations of cell stack components such as bipolar plates and membrane.

Please see our application advisor document to select appropriate materials for your fuel cell application. Besides for fuel cells, Freudenberg's carbon fiber based nonwovens are well suitable for other applications such as hydrolysis or energy storage as well.

https://fuelcellcomponents.freudenberg-pm.com/Products/gas-diffusion-layers

艾邦氫能產(chǎn)業(yè)鏈通訊錄,目前有2200人加入,如億華通、清極能源、氫藍(lán)時代、雄韜、氫牛、氫璞、愛德曼、氫晨、喜馬拉雅、明天氫能、康明斯、新源動力、巴拉德、現(xiàn)代汽車、神力科技、中船712等等,可以按照標(biāo)簽篩選,請點擊下方關(guān)鍵詞試試

艾邦氫能產(chǎn)業(yè)鏈通訊錄,目前有2200人加入,如億華通、清極能源、氫藍(lán)時代、雄韜、氫牛、氫璞、愛德曼、氫晨、喜馬拉雅、明天氫能、康明斯、新源動力、巴拉德、現(xiàn)代汽車、神力科技、中船712等等,可以按照標(biāo)簽篩選,請點擊下方關(guān)鍵詞試試