Albis Plastic 開(kāi)發(fā)用于燃料電池應(yīng)用的化合物

這些化合物目前正在與多家原始設(shè)備制造商合作進(jìn)行驗(yàn)證。

克萊爾·戈德斯伯里|?2019 年 12 月 3 日

Albis Plastic(德國(guó)漢堡)宣布開(kāi)發(fā)用于燃料電池應(yīng)用的塑料解決方案,目前正在與知名 OEM 的項(xiàng)目中進(jìn)行驗(yàn)證。驗(yàn)證過(guò)程包括 Albis 的技術(shù)化合物 Altech、Alfater SL TPV、Tedur L PPS 和 Alcom,所有這些都可以適應(yīng)客戶的特定要求。

電池動(dòng)力汽車目前正在大規(guī)模推向市場(chǎng),如大眾 ID、奧迪 e-tron、寶馬 i3、歐寶 Ampera-e 和梅賽德斯 EQC 車型。Albis 表示,毫無(wú)疑問(wèn),駕駛這些車輛時(shí)可以減少 CO?2排放,前提是能源來(lái)自可再生能源。

然而,該技術(shù)帶來(lái)了許多需要解決的挑戰(zhàn),該公司補(bǔ)充說(shuō),包括資源的采購(gòu)、每次裝載的最大范圍以及相關(guān)的裝載時(shí)間。

|

|

|

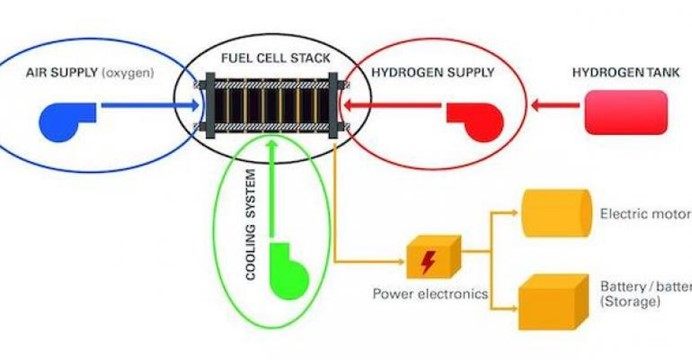

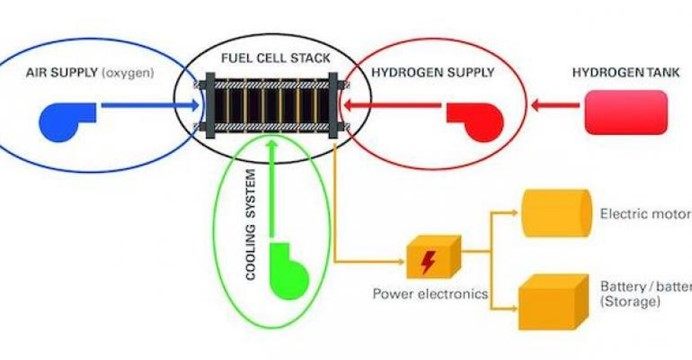

燃料電池系統(tǒng)需要在燃料電池核心本身以及氫氣、氧氣、空氣供應(yīng)和冷卻回路中使用多種材料,包括金屬、塑料和密封材料。?圖片由 Albis Plastic 提供。 |

"結(jié)合電池和燃料電池的混合解決方案在這里是一個(gè)很有前途的解決方案,"Albis 管理委員會(huì)成員兼復(fù)合業(yè)務(wù)負(fù)責(zé)人 Ian Mills 說(shuō)。

燃料電池系統(tǒng)需要使用多種材料,包括金屬、塑料和密封材料。它們既用于燃料電池核心本身,即所謂的"堆",也用于氫氣、氧氣、空氣供應(yīng)和冷卻回路。它們還用于泵、閥門(mén)、壓縮機(jī)、管道和連接器等部件。

諸如揮發(fā)性成分或離子之類的污染物會(huì)通過(guò)排放導(dǎo)致燃料電池的退化,從而通過(guò)改變"雙極板"的表面等方式降低其使用壽命和性能。這些揮發(fā)性成分可以從燃料電池的各個(gè)組件中使用的材料中遷移出來(lái)。

"由于有大量單獨(dú)的零件和附件,幾乎不可能用完全零排放的組件生產(chǎn)燃料電池系統(tǒng),"汽車業(yè)務(wù)開(kāi)發(fā)經(jīng)理 Thies Wrobel 解釋說(shuō)。"因此,必須仔細(xì)檢查所用材料的排放量。"

另一個(gè)重要因素是在清潔的生產(chǎn)環(huán)境中使用相同的原材料以一致、可重復(fù)的工藝生產(chǎn)材料。考慮到這些因素并與 OEM 合作,Albis 開(kāi)發(fā)了已在冷卻和供氣系統(tǒng)中進(jìn)行測(cè)試的材料。

這些材料包括來(lái)自 Altech PP 產(chǎn)品組合的聚丙烯化合物,其中含有 20%、40% 和 50% 的玻璃纖維;Tedur L 產(chǎn)品組合中的 PPS 化合物,含有 30% 和 40% 的玻璃纖維以及 15% 的 PTE(用于軸承應(yīng)用);和 Alfater TPV,一種過(guò)氧化交聯(lián)的熱塑性硫化橡膠,具有與彈性體/橡膠相媲美的肖氏 A 60 和 70 硬度(用于密封應(yīng)用)。

未來(lái),Albis 實(shí)驗(yàn)室將在專門(mén)安裝的測(cè)試臺(tái)上測(cè)試其他化合物。

Albis Plastic develops compounds for fuel-cell applications

The compounds are currently being validated in collaboration with several OEMs.

Clare Goldsberry?| Dec 03, 2019

Albis Plastic (Hamburg, Germany) announced the development of a plastic solution for fuel-cell applications, which is currently being validated in projects with well-known OEMs. The validation process includes Albis' technical compounds Altech, Alfater SL TPV, Tedur L PPS and Alcom, all of which can be adapted to customer-specific requirements.

Battery-powered cars are currently being introduced to the market on a large scale, such as the VW ID, Audi e-tron, BMW i3, Opel Ampera-e and Mercedes EQC models. Albis stated that it has no doubt that CO2?emissions can be reduced while driving these vehicles, provided the energy comes from renewable sources.

However, this technology poses a number of challenges that need to be addressed, added the company, including the procurement of resources, the maximum range per load and the associated duration of loading times.

|

|

|

Fuel-cell systems require the use of numerous materials, including metals, plastics and sealing materials, in the fuel-cell core itself as well as the hydrogen, oxygen, air supply and cooling circuit.?Image courtesy Albis Plastic. |

"Hybrid solutions that combine battery and fuel cells are a promising solution here," said Ian Mills, a member of the Albis Management?Board and head of the Compounding business.

Fuel-cell systems require the use of numerous materials, including metals, plastics and sealing materials. These are used both for the fuel cell core itself, the so-called "stack," and the hydrogen, oxygen, air supply and cooling circuit. They are also used in components such as pumps, valves, compressors, pipes and connectors.

Pollutants, such as volatile components or ions, can contribute to the degradation of the fuel cell through emissions and, thus, reduce its service life and performance by changing the surfaces of the "bipolar plates," for example. These volatile components can migrate from the materials used in the individual assemblies of the fuel cell.

"The production of a fuel-cell system from completely emission-free components is almost impossible because of the large number of individual parts and attachments," explained Thies Wrobel, Business Development Manager—Automotive. "Therefore, the materials used must be carefully examined for emissions."

Another important factor is production of the materials in a consistent, reproducible process using the same raw materials in a clean production environment. Given these considerations and in cooperation with OEMs, Albis has developed materials that have been tested in cooling and air supply systems.

The materials include polypropylene compounds from the Altech PP portfolio with 20%, 40% and 50% glass fibers; PPS compounds from the Tedur L portfolio with 30% and 40% glass fibers plus 15% PTE (for bearing applications); and Alfater TPV, a peroxidically cross-linked thermoplastic vulcanizate with comparable properties to elastomer/rubber in Shore A 60 and 70 hardness (for sealing applications).

Additional compounds will be tested in the future at Albis' laboratory on a specially installed test rig.

艾邦氫能產(chǎn)業(yè)鏈通訊錄,目前有2200人加入,如億華通、清極能源、氫藍(lán)時(shí)代、雄韜、氫牛、氫璞、愛(ài)德曼、氫晨、喜馬拉雅、明天氫能、康明斯、新源動(dòng)力、巴拉德、現(xiàn)代汽車、神力科技、中船712等等,可以按照標(biāo)簽篩選,請(qǐng)點(diǎn)擊下方關(guān)鍵詞試試

艾邦氫能產(chǎn)業(yè)鏈通訊錄,目前有2200人加入,如億華通、清極能源、氫藍(lán)時(shí)代、雄韜、氫牛、氫璞、愛(ài)德曼、氫晨、喜馬拉雅、明天氫能、康明斯、新源動(dòng)力、巴拉德、現(xiàn)代汽車、神力科技、中船712等等,可以按照標(biāo)簽篩選,請(qǐng)點(diǎn)擊下方關(guān)鍵詞試試